GARMENTS MANUFACTURER IN BANGADESH

ORDER TO MAKE (CUSTOM CLOTHING MANUFACTURER)

WE ARE A DIRECT FACTORY

ORDER SOURCING | EXECUTION | DEVELOPMENT | MANUFACTURING | SHIPMENT

We Are A Professional Garments Manufacturer In Bangladesh

Welcome to Jusitex, We are readymade garments manufacturer in Bangladesh. As a leading manufacturer of all types of garments, along with cutting-edge services including cutting, printing, and embroidery, we are your trusted partner in bringing your design visions to life. Based in Bangladesh, we take pride in catering to a global clientele, delivering excellence in every stitch and print.

It’s difficult to start a custom clothing business if you don’t have a dependable product manufacturer. Even if already don’t have a reliable custom clothing manufacturer, You won’t ever fulfill the selling target. That’s why you should find out a perfect custom clothing manufacturer who can support you to make your required quantity with the best materials. Jusitex Clothing Manufacturer is one of the best custom clothing manufacturers in Bangladesh. You can check our Per day production Capacity below which can give you a clear concept for Small, Medium & Big quantity clothing manufacturing.

- Knit Items (Tops/Bottom): Per day Production Capacity: 3000 Pcs

- Woven Tops: Per day Production Capacity: 1200 pcs

- Woven Bottoms per day production Capacity: 1000 Pcs

- Cap/Headwear Products Per day production capacity: 20,000 Pcs

If you have a business in Custom clothing selling & Distribution, you never find a small quantity with the best quality clothing manufacturer to produce your goods very quickly. With 5 production lines, we feel proud to provide the best quality as a readymade garments manufacturer on a custom make based. We’re ready to fulfill your demands with the best quality materials.

Full Package Custom Clothing Manufacturer In Bangladesh.

We are able and ready to do your full-package clothing manufacturing on your own label/tag to keep your good status in your market. We offer readymade garments manufacturing with full customization of the products. Our service included fabric manufacturing to shipment (trims & Accessories sourcing and development, CAD Pattern to easy size grading. Sample Development and get approval, pre-production sample support, and production samples support.

We deal with manufacturing at our own factory with separate departments like:

- Fabric inspection department.

- Cutting department and parts QC department with replacement.

- Embroidery & printing (Additional program) department if applicable.

- Sewing department (Functional-as per operation base of the products)

- Washing & checking department.

- Finishing & packing department.

Then ready for final inspection and send the shipment to the required destination.

Note: For new start-up clothing brand can get maximum production facility form our factory. Own Label Tag, Custom design, Printed Poly, Product box, Custom Carton facility available with us. We’re Professional.

KNIT ITEMS (TOPS/BOTTOMS) GARMENTS MANUFACTURER IN BANGLADESH

WOVEN ITEMS GARMENTS (TOPS/BOTTOMS) MANUFACTURER IN BANGLADESH

WORKWEAR MANUFACUTRER IN BANGLADESH

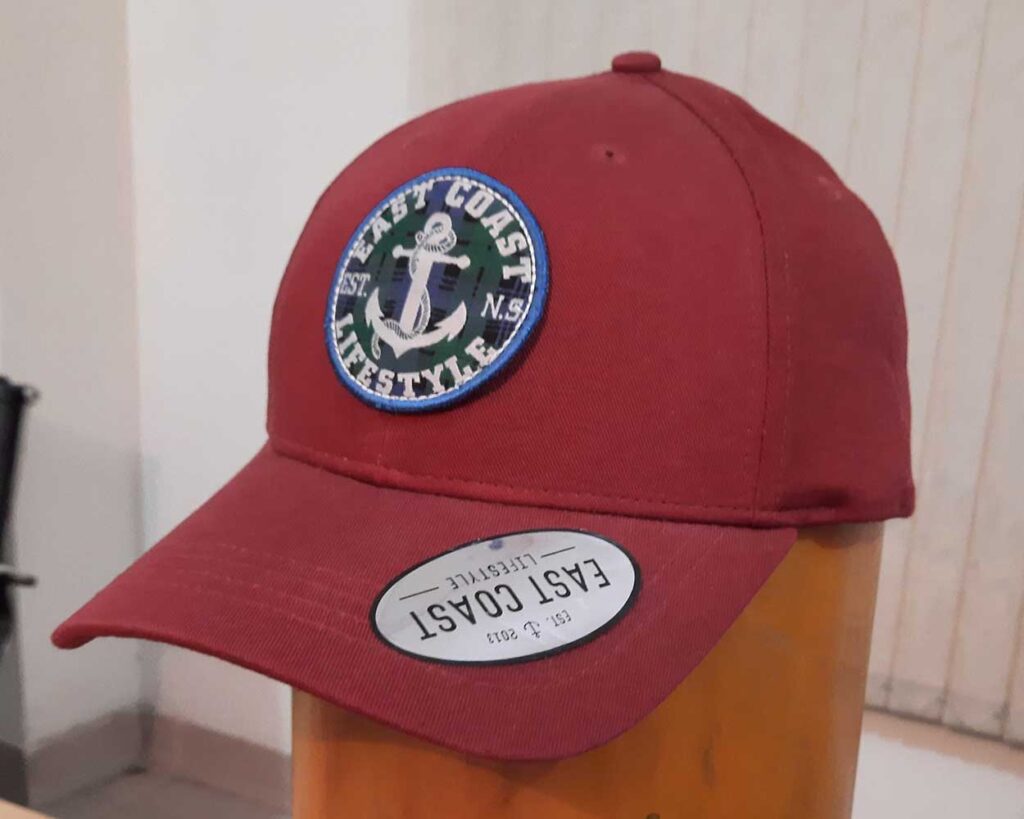

BEST CAP / HEADWEAR MANUFACTURER IN BANGLADESH

Order cheap customized clothing online to save time and money

For your clothing brand, we’re able to give you satisfactory service on development to shipment with good quality products. Specially we follow our client’s Prints, Embroideries, Labels tag designs, product sizes, and best packing. Just you need to give us the information which you need. Our team is also too much creative and with their touch, you may enjoy customer satisfaction from every shipment.

So you can start with us to fulfill your custom clothing manufacturing demands. Jusitex clothing manufacturer always ready to give you best support.

PRODUCT CATEGORIES WHICH WE MAKE

Workable clothing brands are selected from the variation of the product categories that we make regular in our production. You can select and check from below………………….

Your Gateway to Custom Clothing Manufacturers:

At Jusitex, we go beyond manufacturing; we craft experiences. Explore our diverse offerings and immerse yourself in a world where customization knows no bounds.

Jusitex stands as a beacon for both small and large fashion brands worldwide. Our journey spans decades of fashion adventures, making us the go-to destination for custom apparel. From logos and prints to labels, we breathe life into your brand’s unique identity.

Our Commitment to Quality:

As a top-rated clothing manufacturing service, Jusitex is a high quality clothing manufacturers company that’s committed to delivering high-quality services. We understand the importance of customization, and our flexible packages cater to your budget while ensuring maximum customization.

Start on Your Dream Project:

Ready to turn your fashion dreams into reality? Get a free consultation and instant quotes from our top-notch team. We are ready to serve you through various communication methods, ensuring a seamless start to your dream project.

Crafting Excellence in Every Thread:

Discover the spectrum of our services, each designed to elevate your brand and bring your creative vision to life.

OUR SPECIALITY AS A GARMENTS MANUFACTURER IN BANGLADESH.

Our Production Capacity

We’re ready to make for your own clothing brand products. This is direct factory and we’re readymade garments manufacturer in Bangladesh on Custom based manufacturing. For your clothing brand you can check our below production capacity per day.

– Knit garments: 3,000pcs

– Woven bottoms: 1000pcs

– Woven shirts and tops: 1200pcs

– Caps or other headwear: 20,000pcs

The above production capacity only for custom base manufacturing products. For blank/solid products manufacturing we can production 30% Plus then above mention quantity. We are readymade garments manufacturer in Bangladesh

Design & Development

We always prefer the new production design from the clients. Normally they provide us the required design and trims details with fabrics details / garments measurement etc. We also discuss with them as well for clear concept on the new development. Then we go for the new Development project.

Another way we follow. Like client send to us the physical samples and own label tag artwork so we can go development easily by following the reference samples. As a best readymade garments manufacturer in Bangladesh we give best effort to the clients.

Sometime we provide designs and artwork to the client if the clients like our artwork designs then we go development and send the samples.

Quality Controlling

We know quality controlling is a backbone of garments. So we strongly maintain the quality by our organized quality team. To the each Department we have set up Our specific QC Team to control the products quality as well. As a best Readymade garments manufacturer in Bangladesh we use below QC team

– Fabric inspection Department.

– Cutting parts inspection Department.

– Sewing line products inspection Department.

– After sewing the products inspection

Department.

– After Iron we use a QC team to ensure the

products Quality.

– Final inspection team to inspect the ready

products.

SAMPLE LEAD TIME

See below our factories product development Lead time.

Knit Items:

T-shirt, Polo Shirt, Hoodie, Joggers, Sweatshirt, Shorts, Nightwear, Pant Boxer shorts, Sportswear etc.

We take 15 days to development.

Woven Items:

Casual Shirt, Flannel Shirt, Jacket, Slim Fit Shirt, Regular fit Shirt, Pant, Softshell Jacket, Denim Pants, Cargo Long, Cargo Shorts, Chino.

We take 25 days to development.

Cap/Headwear:

For All kinds of Headwear Products.

We take 15 days to development.

PRODUCTION LEAD TIME

See below our factories production lead time.

Production time depends on Quantity.

Cap/Headwear:

For All kinds of Headwear Products

We take 20 to 90 days to development.

Knit Items:

T-shirt, Polo Shirt, Hoodie, Joggers, Sweatshirt, Shorts, Nightwear, Pant Boxer shorts, Sports wear etc.

We take 30 to 60 days to development.

Woven Items:

Casual Shirt, Flannel Shirt, Jacket, Slim Fit Shirt, Regular fit Shirt, Pant, Softshell Jacket, Denim Pants, Cargo Long, Cargo Shorts, Chino

We take 60 to 90 days to development.

SHIPMENT PROCEDURE

Normally We take orders from clients directly. We never work with 3rd party or Buying agents. Most of the shipments we provide by FOB price. Sometimes we do this on CIF, and CFR Terms.

For shipping costs, we always provide different best shipping company contact details to our clients to get the best and most competitive price. Here the clients can enjoy paying the shipping cost to the Shipping company Directly. For sea and Air shipment we follow the method.

We send goods to the shipper nominated Deport which the shipping company noted by our clients. Our C&F ready all documents and handed them over the document to the client’s nominated shipping company for sails.

Your Gateway to Custom Clothing Manufacturers:

At Jusitex, we go beyond manufacturing; we craft experiences. Explore our diverse offerings and immerse yourself in a world where customization knows no bounds.

Jusitex stands as a beacon for both small and large fashion brands worldwide. Our journey spans decades of fashion adventures, making us the go-to destination for custom apparel. From logos and prints to labels, we breathe life into your brand’s unique identity.

Our Commitment to Quality:

As a top-rated clothing manufacturing service, Jusitex is a high quality clothing manufacturers company that’s committed to delivering high-quality services. We understand the importance of customization, and our flexible packages cater to your budget while ensuring maximum customization.

Start on Your Dream Project:

Ready to turn your fashion dreams into reality? Get a free consultation and instant quotes from our top-notch team. We are ready to serve you through various communication methods, ensuring a seamless start to your dream project.

Crafting Excellence in Every Thread:

Discover the spectrum of our services, each designed to elevate your brand and bring your creative vision to life.

Navigating the Perfect Clothing Manufacturers for Small Businesses

As your trusted partner, Justiex is the best option for a clothing manufacturer for small business that caters to all your requirements. Our well-structured manufacturing method, coupled with connections to top fashion profiles globally, ensures a seamless experience with small quantity clothing manufacturers.

From tech-pack creation to sample production and the final stages of manufacturing, we keep you informed. Our in-house graphic designers and clothing vendors bring expertise to every step of the process.

Global Fabric Sourcing

No more worries about clothing material unavailability. Jusitex is connected with fabric resources worldwide, making it easy to source fabrics from any corner of the globe, regardless of rarity or expense.

End-to-End Solutions

What sets us apart as the best custom clothing manufacturer in Bangladesh is our commitment to providing complete end-to-end solutions. From concept designing to final products, Jusitex handles design, sewing, cutting patterns, fabrication, customization, grading, sizing, color, packaging, and manufacturing.

Custom Clothing Manufacturers Near You

If you’re searching for wholesale clothing manufacturers, add Jusitex to your “custom clothing manufacturers near me” list. We understand precisely what customers love to wear, helping your brand create a top-class clothing line with a fast turnaround time.

Connect with us through the form below, and let us guide you on creating a finished clothing line that resonates with your brand identity. for wholesale custom apparel manufacturers.

Why Choose Us?

- Quality Clothing Manufacturer: Jusitex is your one-stop organic shop, providing long-term solutions for all your apparel needs.

- Low MOQ (Minimum Order Quantity): It totally depends on the product’s quality and quantity. We cater to orders as low MOQ for per pieces, per color and design, ensuring flexibility and bulk savings.

- Quality Assurance Guarantee: We maintain control over the entire designing and production process, checking the quality of each product 3 to 4 times before the shipment process.

- Security of Your Design: Jusitex assures you of copyright design security, respecting all your privacy concerns.

Your Budget-Friendly Clothing Partner

For larger orders, we offer attractive pricing tiers and discounts. Growing with us, we can be your all-time custom clothes maker, ensuring better margins as your brand and business flourish. As one of the top choices for luxury clothing manufacturers and custom clothing manufacturers for startups, we provide complete customization across all types of clothing.

Extensive Clothing Experience and Knowledge

As a professional apparel manufacturer, Jusitex can produce almost any type of custom clothing. Our production team will guide you through the process, providing regular updates at every stage. Whether you prefer fully customized clothing or a diverse clothing line, we are your top-tier manufacturer, serving as global clothing suppliers worldwide.

Get precisely what you need, in the quantity you demand, all in one place. Choose Jusitex for an entire collection rather than working with multiple suppliers.

Our Process: Crafting Every Thread with Precision

- Fabric Selection: Your dedicated representative helps you choose the best fabric for your product.

- Cut & Sewing: Once the fabric is selected, it undergoes cut and sew processes to ensure no compromise in product quality.

- Customization: All desired changes in terms of printing, add-ons, and alterations are executed effectively.

- Labelling: Before reaching the packaging department, each product is labelled with care.

- Packaging: The final product is ironed, folded meticulously, and packed according to your preference for a premium look.

- Shipment: Packed and ready orders are sent for shipment to your location with minimal shipping time.

FAQ

What Is Your Low MOQ for Clothing Manufacturing?

We offer a low MOQ of 300 or above, ensuring bulk savings, improved cash flow, and protection from the risks associated with bulk production. Order the minimum quantity and ensure the quality of fabric, stitching, and designs.

How Do I Contact You for Apparel Manufacturing?

Reach us through various channels:

- Email: info@jusitex.com

- Inquiry form: https://jusitex.com/

- WhatsApp: +8801712396281

- Live chat (Monday-Friday: 8 am – Midnight)

Which Payment Methods Do You Accept?

All are commercial Shipment (Wire Transfer or LC at sight)

Do You Provide Tech-Pack and Mockup Services?

Yes, before the sample is made, we provide a mock-up and tech-pack file containing details about size, color, fabric, measurements, colorways, materials used, packing instructions, and more.

What Are Your Business Days and Turnaround Time?

Our business days are from Monday to Friday. The entire process, from submission to completion, takes 30 – 35 days. Product sampling requires 15 business days, and bulk production takes around 15 to 17 days.

For professionals in apparel designing and custom t-shirt manufacturing services, Jusitex is the right choice for the finest and long-lasting product quality.